Urgence gaz 0 800 028 800

IoT, a new tool for industry

Just like the home of tomorrow, the industry of the future will be connected. IoT, the Internet of Things, is becoming an increasingly important relay, providing a more exhaustive and accurate view of physical installations in the field. Teréga is firmly committed to this approach and has already launched several projects in collaboration with a specialist partner: IoT Valley.

Pierre Farbos, Process Support Manager in Teréga’s Services and Transformation Department, and Marine Dufau, Project Manager at IoT Valley, provide an overview.

What exactly is meant by IIoT, Industrial Internet of Things?

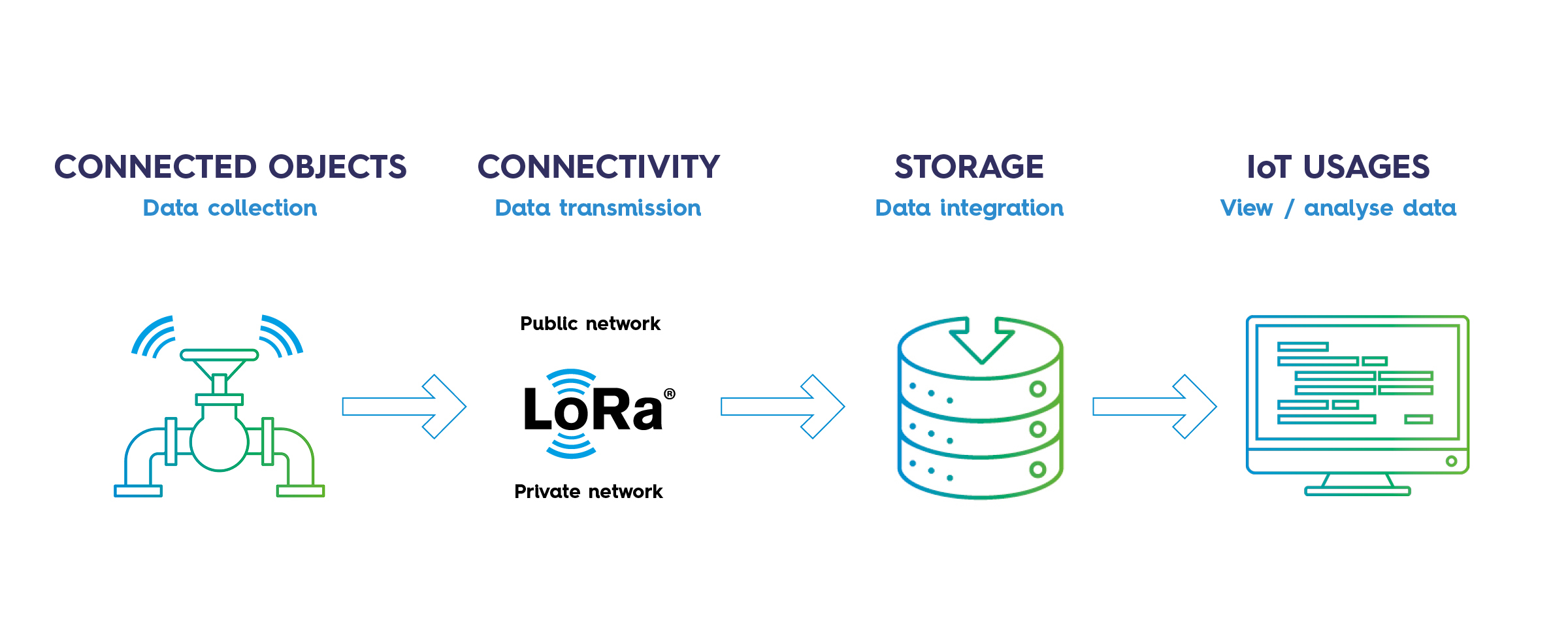

“IIoT, the Industrial Internet of Things, enables us to capture a certain amount of data in the

physical world that was previously unused, and process it to extract value. This data is

collected by sensors placed on the installations, then sent to transmission relays, all the way to the cloud. The manufacturer can then retrieve the data and use it, for example, to support

decision-making or predictive maintenance,” explains Marine Dufau.

Already widely used in the building sector, IoT is now rapidly becoming widespread in industry, particularly at Teréga.

What forms does IoT take at Teréga?

As part of the “Industry 4.0” initiative, Teréga has launched a project to provide the company

with a digital twin containing all the data it needs, from operations to finance. "With this in mind, we have launched ’Project 4.0, an initiative to select investment projects that will serve as platforms for experimenting with new technologies,” says Pierre Farbos. We have tested, analysed and evaluated their possible contributions. We also questioned the jobs, to define those that could benefit from the data collected thanks to the IoT.”

These discussions helped to identify possible uses: in particular, IoT can be used to fine-tune network supervision (work, simulation, etc.). In some cases, the collected data can also limit or even avoid the need for human travel, in particular to monitor pressure on installations.

Partnership with IoT Valley

To implement these new technologies, Teréga has entered into a partnership in 2019 with IoT Valley, an ecosystem of start-ups based in the Toulouse region, specialising in the digital

and IoT fields.

“Together, in the field, we identify and characterise the needs of Teréga that could benefit from digital solutions. IoT Valley then goes in search of start-ups offering technologies capable of meeting these demands. We are supporting the implementation of these technologies, particularly through supervised and measured tests to assess the contribution.

This is the POC (Proof Of Concept) phase, which is crucial for getting teams on board and

validating the performance of a solution before wider deployment,” explains Marine Dufau.

Setting this up requires a range of skills: managing a fleet of sensors, choosing communication networks, IT processing and data interpretation. All this work is carried out in close collaboration between the two entities. Alongside the actions of IoT Valley, Teréga’s Technical Coordination qualifies the equipment and describes the operating and maintenance procedures. The Services and Transformation Department (DST) ensures that the service is delivered from A to Z, including the communication network and IT aspects.

A few examples of current projects

1 - Pressure sensors to refine supervision

One of the first IoT projects carried out by Teréga and IoT Valley was to install wireless pressure sensors on non-remote transmitted shut-off stations, and enable the SMG (Teréga’s gas flow supervision service) to consult this data.

After several months of collaboration with the business lines and testing at the Urgosse pilot site, 20 pressure sensors are now in operation on several types of structure:

Mobile equipment (mobile stations, tankers) used as back-up during works.

Certain sectioning stations to enable the ‘Network Simulation’ team in the Gas Movement Service to refine its models and analyses.

Delivery stations in certain pilot areas, in response to specific needs expressed by operational staff (for example, in Bordeaux, operational staff were able to position sensors to continue collecting data when there were breakdowns on the telecommunication network or to collect additional data to help them manage operations).

In addition, 30 valve position sensors were deployed to record valve opening and closing.

Julien JoyetBordeaux Territory Manager“Over the past few months, we have been working on the use of data from IoT sensors installed on shut-off stations. The main way of monitoring these facilities is via the communications networks, which are subject to breakdowns. Energy-independent IoT sensors have allowed us to continue receiving the data essential to our business automatically, even if the telecommunication network failed. This solution saves us having to send technicians out to carry out inspection surveys. The same applies to some of our equipment that is not connected to the network, but for which the IoT still allows us to collect data."

2 - Vibration sensors for predictive maintenance

Since 2021, a new IoT project has been underway at the Lussagnet storage site, aimed at optimising vibration monitoring of piping in response to compressor use.

It implements a vibration detection solution comprising 19 sensors, coupled with AI (Artificial

Intelligence) that predicts the arrival of vibrations critical to the infrastructure, based on the site’s operating parameters. Predictive maintenance is also being studied for other equipment, such as the TEG 1 pumps and the site’s compressors.

“With Teréga, we are now exploring other needs, such as the detection of water leaks on

the Lussagnet fire network, or the detection of undeclared work on the gas network. The

subjects are fascinating! Teréga is one of our most emblematic partners, because of the

commitment of its teams to testing ever more innovative solutions. ” concludes Marine

Dufau.